The Appraisal Balancing Act

I had sooooo hoped this would be the final Part to this saga. But that would appear not to be the case. Let’s recap…

The Appraisal process, at best loose science and conjecture, at worst complete black arts, has always been cloaked in secrecy and rather subjective. Toss in a Modernist home (more valuable per square foot – as buyers will pay more), and a LEED Platinum home that is almost Net Zero, NOT in a neighborhood and on acreage – oh and with nonstandard construction techniques and you have a “complex appraisal”. Which I now understand this to mean that it 1) takes longer and 2) costs more.

Add the layer of the appraisal “clearinghouse” to improve the ethical dealings of banks, appraisers, mortgage brokers, builders and real estate agents and it seems to be very well designed to not hold anyone accountable for the accuracy of validity of the data in the appraisal. (Can you tell I am less than thrilled here?)

While you can’t select a specific appraiser (again – that ethics thing), you can have certain requirements for an appraiser. In our case, we felt it was imperative that the appraiser had SOME training and familiarity with “green” or sustainably built homes. Once again – there’s no one certification or accreditation available from the professional association – but there is the 5 page Energy Efficient Addendum that can be used to augment the appraisal and help apply value to each energy efficiency feature.

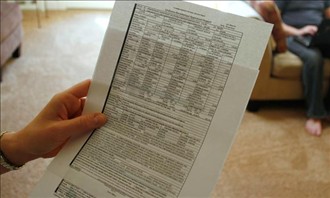

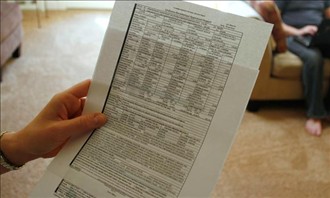

We got our appraisal back after providing the appraiser a copy of our preliminary Energy Star report / HERS Index (33 without photovoltaic, and -7 with PV) and also our detailed preliminary LEED classification with all the detail from our LEED AP consultant. All this information would allow the appraiser – remember the “green appraiser” – to fill out the 5 page addendum and accurately attribute value to the energy efficiency.

One page – Should this be a valuation of your entire project?

If you are not familiar with the manner in which the appraiser goes about valuing a property – I’ll net it out. The appraiser takes comparable properties (comps), and through a series of comparisons to your project / home / plan, normalizes the other homes to have them more closely match your home through a series of additions or subtractions. For example – our house has a pool in the plan. One of the comps did not. So, the appraiser “added” $25k to the sales price of the comp to try to account for the missing pool – i.e. since a pool would raise the price and since we have one – this is the normalization. Since it’s rare to have a 100% equivalent property sell within a year – it’s important to pick the right comps. And yes – some of the attributes that drive additions or subtractions are subjective, you hope that the overall process is sound.

Or not.

There is one line entitled “Energy Efficiency” in the one page that is really the meat of the final assessment (as far as we were concerned). This is where we were expecting to have the appraiser utilize the 5 page addendum so that the amount they could attribute to our project (assuming they could not find a comp that was also Energy Star / Green / highly energy efficient, etc) would be reasonable. We didn’t expect it would really cover the costs of the investment we are truly making. After all – this investment will pay us back over the entire life of the home with, potentially, having zero or VERY LOW energy bills, and very little maintenance. So – yes- we’re going to pay more because ultimately, we’re going to get more. I am okay with that. What I am NOT okay with is how the appraiser populated the energy efficiency line item.

- Comp 1 – new construction. Labeled as “Good” in Energy Efficiency. $0 added to the comp sales price. Upon further investigation from the home’s MLS listing, there is no mention of ANY green or energy efficient feature. There is nothing to indicate this home was built to any standard higher than the local / state building code.

- Comp 2 – 12 year old Modernist home. Labeled “Average” in Energy Efficiency. $75k added to comp sales price. No updating was done to this home and I happen to know this home had monthly utility bills of well over $1000.

- Comp 3 – 5 year old single story Modernist home. Labeled “Average” in Energy Efficiency. $75K added to comp sales price. This home also averaged utility bills in the $1000 per month range.

Flipping through the appraisal – the Energy Efficiency Addendum WAS included. 5 Pages. The appraiser filled out one question checked one box for LEED certification. That’s it. Nothing on R values. Nothing on my window u values, r values, triple paned, krypton filled lusciousness (grin). Nothing on solar photovoltaic and the potential to EARN MONEY or have $0 energy bills. Nothing in the State and Federal rebates for which the house will be eligible. Zip. Zero. Zilch. Again – even though this was provided in the LEED checklist and the LEED AP contact was made available.

So – what do you do? I realize that appraisals are somewhat subjective – after all – you have to take “similar” comps and make educated guesses on how to adjust these disparities. But – essentially what was done here is that the appraiser gave us no credit for anything – ANYTHING – that we have done that is over the crappy state building code. Yes- the home is more energy efficient than one built 10 years ago – but it’s also a TON more efficient that a ‘base’ home built today.

Because of all the regulation – the bank cannot “contest” this. I guess I have to. And I also realize that this is going to be coming dangerously close to me telling someone that is a professional how to do his / her job. But seriously – this is a person who has touted their education and familiarity with green homes, building techniques and valuating these features! I am also sure that any changes to this appraisal will have to be accompanied by an explanation – and then ‘certified’ by the third party that acts as a clearinghouse AND quality control point to reduce industry corruption – so it may raise scrutiny. (and it’s extra work – but – when you charge extra for a ‘complex appraisal’ – I expect you to actually DO SOMETHING) However, I am going to present this as an ‘error’ and not something that I am essentially arguing a subjective “I don’t think you valued my project high enough” – but instead – focusing on specific things that simply don’t add up.

I’ll let you know how that works out.

We’re close – we’re really close – and I think we can make it work at the present value if we HAD TO – but it sure would be nice to be given SOME credit. Perhaps rating out home “Excellent” compared to the new code built home that was rated “Good” in that same category, and then, filling out the addendum to justify both the “Excellent” rating and the increase valuation. Novel idea. The appraiser did include a bunch of copy / paste words about increased market value of green homes, and green homes spending less days on the market (DOM) that standard homes, and then, of course, didn’t pay any attention to them.

And then – if we can get the appraisal saga done – according to the bank – we can close a loan in 2 weeks. WHOO – freaking – HOO!