A house is made up of glass and concrete and steel and wood (well, not ours) and a host of other materials. You assemble the pieces and you “build”. But it’s the people involved in the project, that can set it apart. The people either rise to meet the challenges or they produce the minimum they can to get by and don’t inspire others, and likely don’t garner a lot of personal satisfaction from their “job”.

Think Big!

We’ve been very fortunate on this project to have met some incredible people. People who’s skill and caring have helped us realize this crazy dream. People who took at little extra time to understand what we’ve been trying to do, and figured out creative ways to help meet the goal. They’ve stepped outside their personal or professional, comfort zones and took us seriously when we asked ‘why not?’.

We hope that we can partner with some of these folks as we move through the process and at project completion when we do “the fun stuff” – like the open house tours with NC Modernist Houses, or open house required by LEED, or maybe the Green Home Tour (although no sure I’ll be spending the money to put our house on the tour…)

The house is “stuff”, but the process is people. And continue to be pleased and comforted by the folks who are passionate about what they do – and strive to differentiate themselves against “the rest”.

Honestly, I am at the end of my “playing nice” rope. Appraisal saga continues. As noted before – we had some issues in the comps – specifically the Energy Efficiency line item for comparison vs other new homes that do not appear to have any energy efficiency features AT ALL.

Honestly, I am at the end of my “playing nice” rope. Appraisal saga continues. As noted before – we had some issues in the comps – specifically the Energy Efficiency line item for comparison vs other new homes that do not appear to have any energy efficiency features AT ALL. I would like to get back to the “fun” stuff. Some more design decisions, envisioning how we’re going to finish the rooms – bathrooms, kitchen, etc. And I would REALLY like to see some dirt moving. I think that once that happens, I will know it’s real. And it will be easier to engage with the rest of the suppliers, ask for best and final pricing, and nail down some details. It’s hard to maintain focus on the project until this financials are done and WORK starts. I know Tonic is eager to start too – and are feeling a little bit like Charlie Brown and the football.

I would like to get back to the “fun” stuff. Some more design decisions, envisioning how we’re going to finish the rooms – bathrooms, kitchen, etc. And I would REALLY like to see some dirt moving. I think that once that happens, I will know it’s real. And it will be easier to engage with the rest of the suppliers, ask for best and final pricing, and nail down some details. It’s hard to maintain focus on the project until this financials are done and WORK starts. I know Tonic is eager to start too – and are feeling a little bit like Charlie Brown and the football.

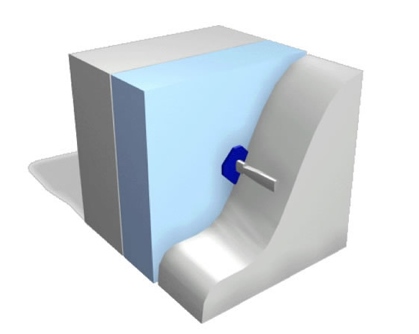

I look at conventional 2×4 construction as “lowest common denominator” construction – while it is cost effective I find it to be incredibly wasteful and sloppy. It also has a fundamental problem that we needed to avoid to achieve our “cooler” concept of thermally isolating the inside of the house from the outside as much as possible. Every 2×4 creates thermal paths between inside and outside surfaces, thus creating thousands of holes in the thermally isolated “bucket” that we are trying to achieve.

I look at conventional 2×4 construction as “lowest common denominator” construction – while it is cost effective I find it to be incredibly wasteful and sloppy. It also has a fundamental problem that we needed to avoid to achieve our “cooler” concept of thermally isolating the inside of the house from the outside as much as possible. Every 2×4 creates thermal paths between inside and outside surfaces, thus creating thousands of holes in the thermally isolated “bucket” that we are trying to achieve.