Having bought into the concept and design aesthetic of concrete exterior walls we started brainstorming about interior walls surfaces. Out initial thoughts were to use wood to warm up the interior of the house and avoid the dreaded sheetrock as a wall material. We bounced around a lot of ideas on how to execute interior wood walls while keeping with the evolving design aesthetics. We came to the conclusion that it would be better to use wood as warming / accent material via furniture, cabinets, doors, etc. where it made logical sense to use it. This then led to the crazy, wild assed idea of using concrete on the interior walls – an idea that grew on us after initially us being skeptical about it. So why not??

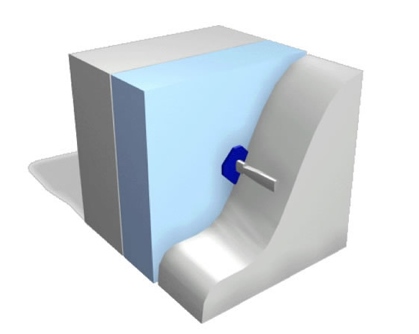

In parallel with our discussions on interior wall materials we had continued our internet search for precast concrete wall manufacturers. And during this we stumbled across a company that claimed that they made concrete sandwich panels – panels that had both a concrete exterior surface (known in the trade as a “wythe”) and a concrete interior surface or “wythe”. And it turned out that this company, International Precast, was fairly local to us – offering the ability to meet with them in person, see their facility, etc. The fact that they were local also helped from a LEED perspective as it minimized the environmental and cost impacts of shipping the finished panels.

So our next steps were an initial telephone call and then a visit to International Precast.  The net out of these discussions and site tour was that it appeared that they could do exactly what they claimed they could do – deliver concrete sandwich panels that could form the outer walls for both buildings for our project. So our crazy wild assed idea to use concrete on our interior walls was actually possible. Not only was it possible – it seemed that properly executed concrete sandwich panels would deliver both our interior and exterior finished walls in a single product.

The net out of these discussions and site tour was that it appeared that they could do exactly what they claimed they could do – deliver concrete sandwich panels that could form the outer walls for both buildings for our project. So our crazy wild assed idea to use concrete on our interior walls was actually possible. Not only was it possible – it seemed that properly executed concrete sandwich panels would deliver both our interior and exterior finished walls in a single product.